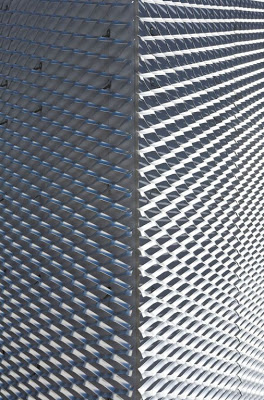

Expanded Metal Mesh Facade System For Parking Garages

The expanded metal mesh system ensures excellent ventilation while providing security, safety, and visibility throughout the parking structure. The aluminum expanded metal provides a durable, long-lasting, and virtually maintenance-free solution to any parking structure exterior. At a major cost savings compared to wire mesh and perforated, choose expanded metal when designing your new project. See below for an interview pertaining to expanded metal facades.

Expanded Metal Facade: An Interview with Florian Idenburg

by Clara Wong, The New Museum of Contemporary Art, New York by SANAA

Project Name: California College of the Arts, Graduate Center Architect: Jensen Architects

Photographer: Mark Luthringer Website: jensen-architects.com

-

For a museum, the facade does not only filter light but also creates an iconic image for the institution. It’s functional and acts as artwork onto itself. As the designer of the New Museum, could you tell us the story of the metal mesh façade?

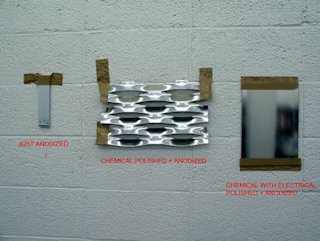

First we wanted a flat metal façade. We wanted the façade to be light, flexible and strong, to protect the art collection against the tough elements of the street. We didn’t want the effect of a heavy building, unlike the Folk Art Museum (Tod Williams Billie Tsien Architects) and its heavy metal façade. We were considering a galvanized façade, but that was not durable enough for the climate. Due to a lot of trucks traffic through the Bowery, the lead content in the air is high. Also the climate is semi-salty since the site is close to the water. A galvanized façade is not sufficient for the Museum, so we explored 5 other kinds of metal facades.

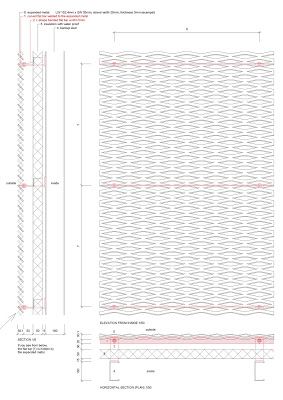

Another concern was how to do away with seams or make them invisible. We wanted the effect of single boxes. In fact we were looking at a single sheet of façade prefabricated for each side of the building. The panels would have been 30’ to 70’ long. We researched the truck routes and road dimensions, and how you can transport these panels to the site. There’s actually a way to get it through by boat at the end of Houston Street. All this would be very costly. So we explore how to get rid of or camouflage visible secondary systems and joints.

Stainless steel has the least thermal expansion, which would help us to get the tightest joints, and have every façade read like one single surface. But that would be an extremely difficult and expensive installation.

We considered 3 things when we deal with metal facades:

1. Thermal expansion,

2. Fabrication tolerances,

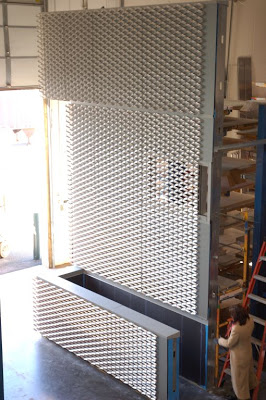

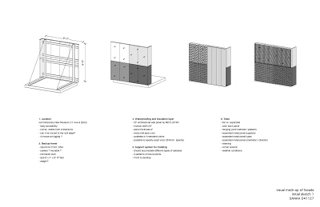

3. Installation tolerances.One of the materials we explored was the standard industrial mesh often used for parking garages and airports. Expanded mesh companies make these meshes in a very straightforward way for industrial application. They are cheaper than perforated metal, just cut and rip sheets of metal, with no material lost, no punching. The aluminum is rolled up in a coil when it comes to the factory, and can be cut as long as we wanted, with a fixed width. The metal sheet is expanded by 30%. However it’s a rough material and the tolerance is not guaranteed. We need to make sure they were precise, and we have to make a reasonable size of panel so people can install it. On the other hand, we want to make as big a panel as possible to avoid joints.

We also had to look at the costs, which meant looking for standard sizes. In the end we divided the front façade (70’ long) into 18 panels (each around 4’ long). We made the mesh overlap, so the diamond pattern is cut at the middle, and hence leave tolerance for panels to overlap. It is basically a shingle installation. We asked for a big diamond size for the mesh, so that the strong graphic of the façade will help camouflage the joints. Finally there’re 6 diamonds per panel width (~4’). There is no frame for each panel, since we did not want an additional system. Of course, we had to test and figure out the stiffness of the mesh. We ended up using a very flexible mesh, with a thickness of around 4mm, manufactured by the Expanded Metal Company UK. The anodizing company is from UK, and also anodized the Selfridges Department Store by Future Systems.

-

For such flexible panels without frames, how do you stiffen them and prevent bending?

We have little clips supporting the panels at every six rows of diamonds. The clips sit right behind the mesh, and have the same angle as the mesh, so they disappear behind it. The mesh has a 3-dimensional shape, which again helps create a strong graphic and to camouflage the joints. Some panels have no overlap and are butt-jointed. We are aware that the metal façade of e.g. Gehry’s Disney Hall was attacked for having too much reflection. The 3-dimensional quality of our mesh diffuses light— light is only reflected at the diamonds’ points and there’s no focal point of reflection. We want a light building, not one with hard reflection.

-

Was this light diffusion an initial goal, or a discovery through building?

We’ve always wanted the building to be like the armor of a knight—light and tough, flexible and strong.

-

You have been talking about effects on the exterior – did you look into the interior effects of the facade?

We designed the building from inside-out – providing well-proportioned gallery spaces with daylight but stacked in a tight New York lot. The Museum wanted a maximized envelope and a variety of gallery spaces…C: So the façade is basically an image for the city, a dress for the exterior? F: Yes, the Museum wanted walls to hang the artworks, and vertical openings will reduce surfac area for art. We had very little room to explore the window. The shifts of the building volume create skylights that have metal grating, since firefighters need to be able to jump on top of the gratings. It’s actually illegal to have skylights at the edge of the building, so we use deep industrial gratings to make walkable surfaces. The gratings are deep, cutting direct sunlight and doubling as louvers.